IT Digital Manufacturing solutions

Industry 4.0 solutions that help manufacturers ensure business continuity, run smarter, more autonomous operations and gain better insights from data across the enterprise.

Transforming IT for manufacturing at the industrial edge

The future of manufacturing is connected, automated and digitally driven. As plant floor operations technologies converge with IT, numerous use cases across the manufacturing cycle become possible to ignite innovation, create more efficient operations, reduce downtime and improve worker productivity.

Enabling the intelligent factory

HPE helps manufacturers optimize operations, improve product quality and worker productivity. Our edge-to-cloud industrial IoT solutions enable:

- Digital design and simulation: Remote visualization, CAE and EDA solutions for faster, more reliable design, modelling and simulation

- Guided assembly: Augmented reality-based instructions help workers master multiple product configurations and assemblies to reduce defects

- Maintenance and repair: “See what I see” technologies put line workers directly in touch with remote experts for faster diagnosis and resolution of equipment issues

- Video analytics: Sophisticated video analytics drive speed and accuracy in the quality assurance process

- Condition monitoring and predictive maintenance: Monitor and predict maintenance issues before they occur to reduce unplanned downtime

- Digital twin: Digitalize plant floor asset performance and processes to monitor and adjust production

Connect workers with data and insights

For machine assets and products, connectivity has long driven improvements in efficiency, performance, and productivity. Recent technology developments provide greater capabilities to monitor and control plant floor equipment, products, and even the production processes themselves, providing new data sources from a variety of operations areas.

Drive asset performance with digitization

Advancements in IT and lower device costs have allowed manufacturing companies to aggregate plant floor asset data— assembly-line equipment, tools, and operational systems involved in the manufacturing process — into a common dashboard for improved visibility into plant floor operations and equipment performance.

Use video for quality assurance

Over the past five years, the Internet of Things (IoT) and edge computing have lowered the costs of applying vision to production processes and also improved the speed, data accessibility, and information processing of industrial vision systems.

Leverage SAP as a Service to increase manufacturing agility

Futurum Research explores the impact of digital evolution on manufacturing and the convergence of operational technology (OT) and information technology (IT). The paper also looks at real-world solutions from SAP and HPE to turn data into insights.

A new class of digital manufacturing solutions

We have the technology expertise and the solutions to build an edge-to-cloud manufacturing digital foundation to support your industrial digitalization journey.

Accelerate product development cycles with HPC

Speed time to market without compromising quality. High-performance compute keeps iteration turnaround times low. Model and test with reliable results that quickly aid engineering decisions.

Reduce product defects with AI-powered video analytics

As products become smarter, more complex and personalized it becomes harder for the human eye to spot defects. Increase the speed and accuracy of inspection processes to reduce defects and the need for re-work.

Shorten maintenance cycles with augmented reality

See through remote eyes and improve product support times, accelerate collaboration, trouble-shooting, and problem resolution across engineering, product design, and production teams.

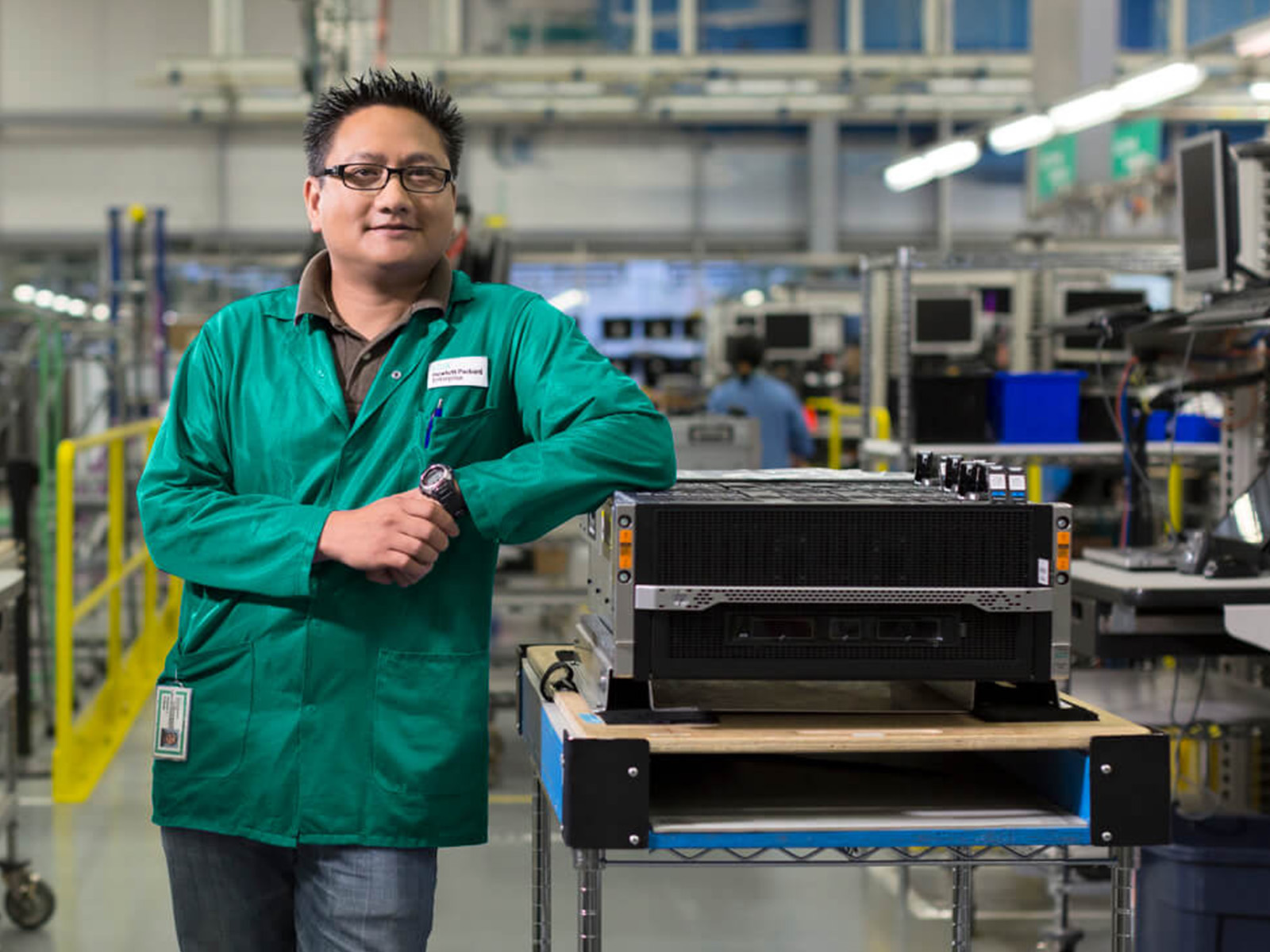

Optimize operations with IIoT technologies

The Industrial Internet of Things presents new ways to drive manufacturing process efficiencies, engage customers, and enable real-time analytics of production data at the edge to reduce unplanned downtime.

Boost manufacturing agility with SAP HANA as a Service

A holistic data management strategy combined with SAP S/4HANA, can unlock the value of manufacturing data across the value chain for faster time to insight.

Get the digital transformation expertise you need

Leverage the experience of an industry leader in digital era advisory and transformation services to help drive better digital experiences for you and for your customers.

HPE GreenLake brings the cloud experience to manufacturing

Get the cloud experience wherever your apps and data live, centralize your operations, and drive innovation with HPE GreenLake.

HPE GreenLake: Empowering transformation to meet digital demands

The Industrial Internet of Things (IIoT) makes vast amounts of data available to manufacturers; the challenge is to transform that data into insights to uncover inefficiencies and support competitiveness. HPE GreenLake offers workload-optimized services that enable faster access to data and insights, combining the automation, agility, and economics of the cloud with the security and performance of on-premises infrastructure. IT can now deliver a modernized solution that is adaptable, scalable, secure, and streamlined to provide business efficiencies from the shop floor to the executive suite.

Connect workers with data and insights

For machine assets and products, connectivity has long driven improvements in efficiency, performance, and productivity. Recent technology developments provide greater capabilities to monitor and control plant floor equipment, products, and even the production processes themselves, providing new data sources from a variety of operations areas.

Drive asset performance with digitization

Advancements in IT and lower device costs have allowed manufacturing companies to aggregate plant floor asset data— assembly-line equipment, tools, and operational systems involved in the manufacturing process — into a common dashboard for improved visibility into plant floor operations and equipment performance.

Use video for quality assurance

Over the past five years, the Internet of Things (IoT) and edge computing have lowered the costs of applying vision to production processes and also improved the speed, data accessibility, and information processing of industrial vision systems.

Leverage SAP as a Service to increase manufacturing agility

Futurum Research explores the impact of digital evolution on manufacturing and the convergence of operational technology (OT) and information technology (IT). The paper also looks at real-world solutions from SAP and HPE to turn data into insights.

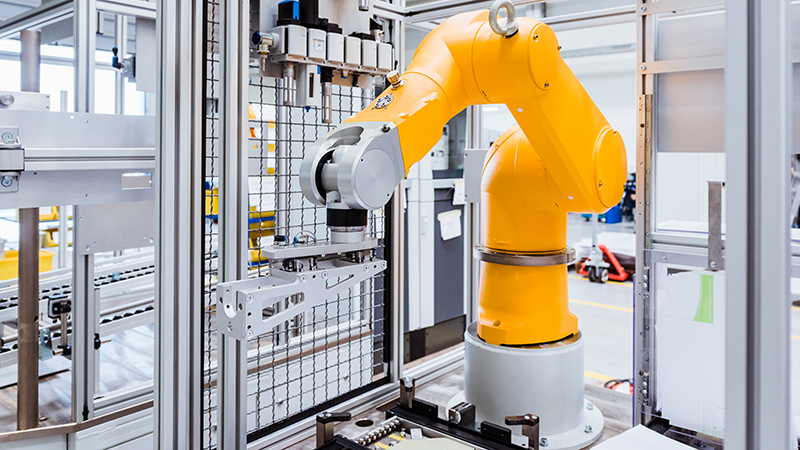

Experience HPE GreenLake cloud services

Take HPE GreenLake for a no-cost, no-obligation test drive. This guided, hands-on experience allows you to explore cloud services in a live production environment.

See how our manufacturing customers are using HPE GreenLake

Browse the below case studies to see how customers are using HPE GreenLake to drive manufacturing efficiencies and business outcomes.

Zenseact builds a safer future on AI and real-time insights using HPE GreenLake

Zenseact is at the center of the crossroads of driver safety and autonomous driving. This Volvo Cars-owned startup built a consumption-based platform to deliver tens of thousands of simulations per second and make cars safer.

- Challenge: A critical need for an innovative technology partner, enabling delivery of thousands of self-driving simulations each second

- Solution: Partner with HPE GreenLake to ensure technology is always available, consumed as a service and paid for over time, ensuring Zenseact is fully equipped for today and into the future

- Outcome: A high performance platform to deliver what the business needs now, and ensure what is possible in this space as a result of the partnership going forward

Danfoss builds climate-friendly data centers

Danfoss has partnered with HPE to design a forward-looking IT strategy, leveraging in-memory computing platforms to support both its business processes and its engineering teams. With world pressure mounting to solve issues like population growth, depletion of natural resources, and urbanization, Danfoss is now equipped to operate as a digitized enterprise.

- Challenge: Align global operations and speed time-to-market with IT infrastructure that meets the highest standards for transparency, scalability, security, and cost-efficiency

- Solution: For its ERP initiative, the company implemented SAP S/4HANA in a Greenfield environment, using HPE hardware, software, and services to do so

- Result: Wrapping its HANA architecture in a pay-per-use model using HPE GreenLake helped the company access cutting-edge technology without large capital expenditures